Apr 30,2025

Apr 30,2025

Carpet is a soft floor covering made of natural fibers such as cotton, linen, wool, silk, grass, or chemical synthetic fibers, knitted, piled, or woven by hand or mechanical processes. It is one of the arts and crafts with a long history and tradition in the world. It is widely used on the floors of residences, hotels, office buildings, gymnasiums, exhibition halls, vehicles, ships, airplanes, etc., and has the effects of sound absorption, sound insulation, warmth preservation, dust prevention, anti-slip, comfort, decoration, and beautification.

Carpets can be divided into commercial carpets, household carpets, and industrial carpets according to their functions. Commercial carpets are limited to hotels, office buildings, offices, restaurants and other places in China. Household carpets, as the name suggests, are used at home and are mostly square carpets. Industrial carpets are limited to decoration in cars, airplanes, passenger ships, trains, etc. Carpets can be divided into wool carpets, chemical fiber carpets and plastic carpets according to their materials. Wool carpets are mostly made of wool. Chemical fiber carpets include nylon carpets, polyester carpets, modified polyester carpets, acrylic carpets, etc. Plastic carpets are made of polyvinyl chloride resins, plasticizers and other auxiliary materials as the main raw materials.

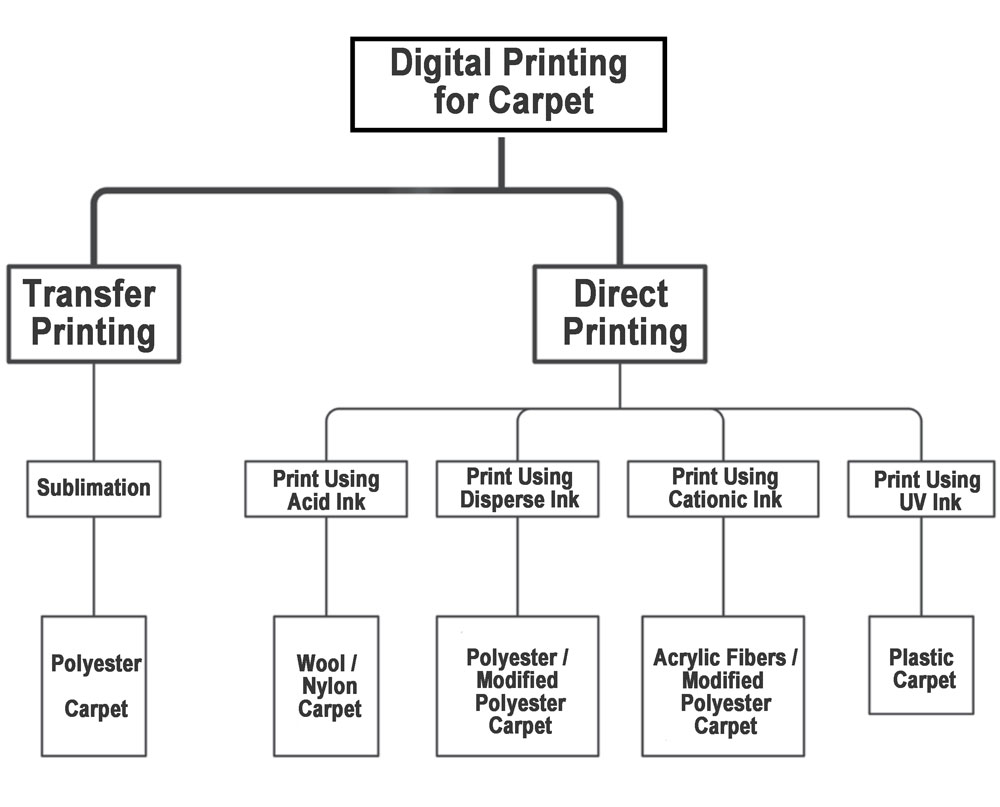

Carpet digital printing technology can be divided into two types: sublimation transfer printing and direct printing according to the carpet fabric material and carpet weaving technology.

The transfer printing (Sublimation) is mainly used for flat carpets made of polyester

This sublimation transfer printing process is simple, no plate making is required, the colors are bright, the equipment is cheap, the threshold is low, and small single fast response can be achieved. The disadvantage is that there is no penetration, and only some flat carpets without fluff or sanding can be made, which are often used for home carpets.

Digital Direct Printing Solution for Carpets

Direct printing is mainly used for velvet carpets. According to the different velvet materials, it can be divided into acid direct spraying, dispersion direct spraying, cationic direct spraying, UV direct spraying, etc. Among them, W direct spraying is mostly used for plastic carpets. Since W direct spraying is not environmentally friendly compared to water-based direct spraying, carpets made by this process are rarely used in confined spaces, so we will not describe this process in detail.

Direct inkjet printing technology can be divided into pressure penetration technology and colorless ink penetration technology according to the principle of penetration. The pressure penetration technology mainly uses physical means to make the ink penetrate into the roots of velvet carpets. The colorless ink penetration technology uses RIP software to control the printing of colorless ink to guide the colored black water to the roots of velvet carpets through the capillary effect. The pressure penetration technology is mainly used for carpets with relatively soft pile, such as flannel carpets. The colorless black water penetration technology is mainly used for engineering carpets such as cut pile or loop pile.

Acid ink direct printing is mainly used forwool carpets and nylon carpets.

Cationic ink direct printing is mainly used in acrylic and cationic modified polyester carpet.

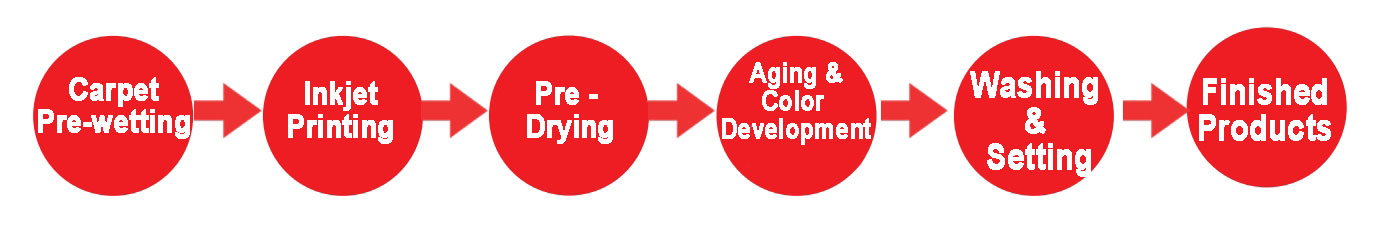

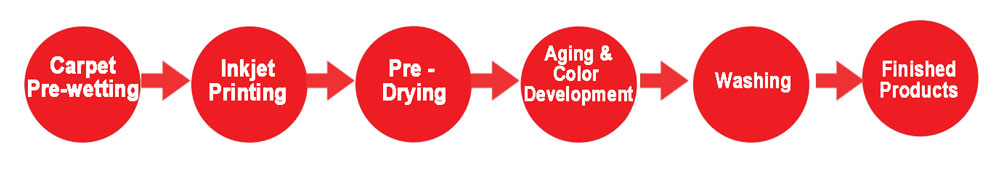

The Process of Cation Ink Direct Printing Solution:

Cationic ink has good permeability, and the need for pre-wetting and printing of colorless ink can be determined according to the weight of the carpet. The cationic ink process is basically similar to the acid ink process.

Dispersed ink direct printing is mainly used for polyester carpets and modified polyester carpets.

The dispersed ink direct printing process can be divided into low-temperature disperse direct pritning, high sunlight fastness direct printing and DTF disperse ink direct printing.

| Direct Printing Disperse Ink Types | Wash or not | Suitable Materials | Color Development Condition |

| Low Temperature Disperse Ink | YES |

Polyester and Modified Polyester |

Polyester: 160-180℃,6-8min Modified Polyester

130-150℃,10-15min

|

| DTF disperse Ink | NO | ||

| High Light Fastness Disperse Ink | YES | Ployester |

Polyester: 160-180℃,6-8min |

The Process of Cation Ink Direct Printing Solution:

The carpet direct printing process is relatively complicated, and the specific process flow depends on the carpet material. Its advantages are good permeability and high color fastness, but the equipment cost is relatively high, and the equipment and supporting equipment need to strictly adapt to the process requirements.

With the progress of society and the formulation of carpet industry standards, carpets are recognized by more and more people and appear more and more in our daily lives. With the advancement of technology, the carpet industry will usher in rapid development.