In the field of inkjet printing technology, precision is the core indicator determining printing quality, and its achievement depends on the synergistic effect of multiple key parameters. This article will systematically analyze the concepts and core parameters related to inkjet printhead precision.

I.The Cornerstone of Precision: Core Definitions of DPI and PASS Count

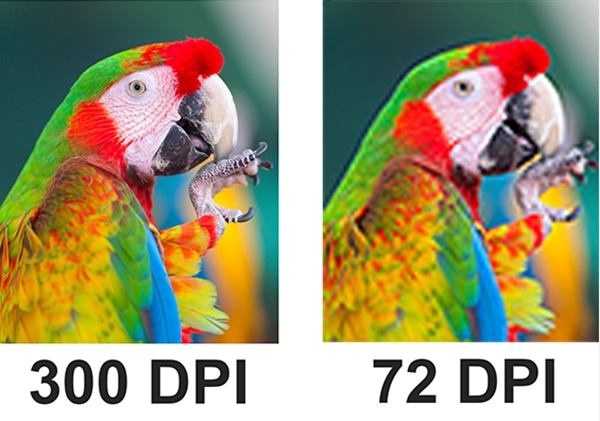

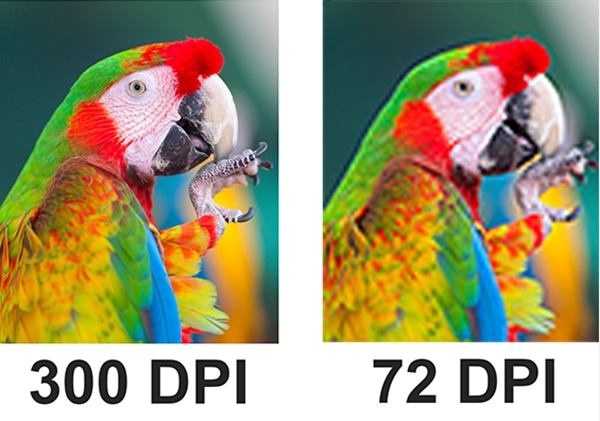

1. DPI: The Quantitative Measure of Printing Precision

DPI (dots per inch) is the most intuitive indicator for measuring printing precision, representing the number of ink dots distributed within one inch of the printing surface, covering the density distribution in both horizontal and vertical dimensions. Similar to the principle of smartphone screen resolution, the higher the DPI value, the greater the density of ink dots per unit area, resulting in finer printing details and sharper edges.

The requirements for DPI vary significantly across different application scenarios: ordinary document printing usually requires 300×300 DPI to meet clarity requirements, while high-end art reproduction or precision electronic circuit printing requires 1200×1200 DPI or even higher precision.

2. PASS Count: The Adjustment Knob for Precision and Efficiency

The PASS count refers to the number of times the printhead sprays inkjet inks in the same area, directly related to the motion mode and printing texture of the printing process. 1PASS means that the nozzle only sprays the target area once, suitable for high-speed mass production scenarios; while 4PASS means that the same area undergoes four superimposed sprays (excluding feathering), which can significantly improve image smoothness and color gradation.

II. Core of Precision: The Three Key Parameters of the Print Head

While DPI and PASS count are the "surface indicators" of precision, the mechanical resolution, ink droplet volume, and jetting frequency of the print head are the "hardcore foundations" that determine the upper limit of precision. These three factors together form the technical triangle of high-precision printing.

1. Mechanical Resolution: The Physical Limits and Breakthroughs of Nozzle Arrangement

Mechanical resolution is directly determined by the nozzle spacing. The smaller the spacing, the more nozzles per unit length, and the higher the theoretical printing precision. However, physical factors such as the thickness of the piezoelectric ceramic limit the unlimited reduction of nozzle spacing. The industry commonly uses staggered nozzle designs to overcome this limitation–by arranging two or more rows of nozzles in an offset manner, the equivalent nozzle density is doubled.

2. Ink Droplet Volume: The Microscopic Key to Detail Representation

Ink droplet volume refers to the amount of ink released in a single jet, usually measured in picoliters (pL). Its size directly determines the ability to reproduce details and the quality of color transitions. Small ink droplets can achieve finer grayscale levels and sharper edges, while large ink droplets are suitable for quickly increasing coverage and meeting high-speed printing needs.

3. Jetting Frequency: The Balancing Point Between Speed and Precision

Jetting frequency refers to the number of ink droplets ejected per second and is a key parameter connecting precision and efficiency. Although the frequency itself does not directly change the resolution, a low frequency will limit the printing speed at high resolutions–when high DPI printing is required, the print head movement speed must be reduced to match the nozzle jetting rhythm.

III. Precision Synthesis: The Collaborative Mechanism of the X and Y Axes

The final printing precision is the result of the synergistic interaction of horizontal (X-axis) and vertical (Y-axis) precision. Like two parts in a symphony, they must work together precisely to achieve high-quality printing.

1. Horizontal Precision (X-axis): Dynamic Balance of Speed and Frequency

Horizontal precision is primarily determined by the jetting frequency and the print head's movement speed. The core constraint comes from the laws of physics–improving precision inevitably requires reducing the movement speed to ensure accurate ink droplet placement.

2. Vertical Precision (Y-axis): Superposition Effect of Physical Precision and PASS Count

Vertical precision mainly depends on the combined effect of the print head's physical resolution and the number of passes (PASS count). When the print head's physical precision is fixed, increasing the PASS count can significantly improve the ink droplet density in the vertical direction.

Optimizing vertical precision also needs to consider coverage requirements. Therefore, in actual printing work, the required PASS count needs to be derived from the horizontal precision (X-axis) and coverage requirements to ensure that both precision and coverage quality meet the standards.

Nov 26,2025

Nov 26,2025