Nov 19,2025

Nov 19,2025

In the field of inkjet printing technology, precision is the core indicator determining printing quality, and achieving this depends on the synergistic effect of multiple key parameters. From the basic definition of resolution to the hardware design of the printhead, and then to the parameter trade-offs in practical applications, each step profoundly affects the final printing effect.

In industrial printing, absolute high precision is not the only pursuit; an optimal balance must be found between precision, printing speed, and cost. Some products on the market tout "ultra-high precision" but sacrifice production efficiency; others emphasize "high-speed printing" but reduce nozzle arrangement precision and droplet control capabilities, failing to meet quality requirements.

Mature parameter adaptation solutions have been developed for various industries:

High-speed printing: such as bottle label printing, using a combination of single-pass mode + 360-600 DPI accuracy + large droplet. Konica Minolta's linear printhead design is particularly well-suited for this type of single-pass printing needs.

High-end packaging printing: such as bottle texture printing, using a 4-8 pass mode + 600-1200 DPI accuracy + variable droplet technology. Epson's VSDT variable droplet technology enables smooth color transitions.

Industrial manufacturing scenarios: such as ceramic printing and textile printing, using a medium pass (2-4 passes) + 600 DPI accuracy + printhead adapted to the inkjet ink type. Kyocera's KJ4B series water-based printheads perform exceptionally well in textile printing.

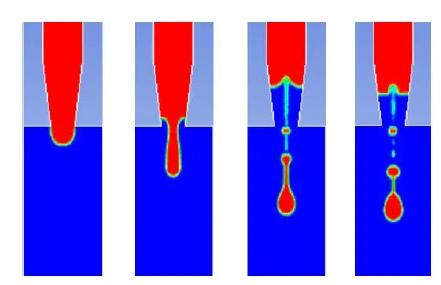

Achieving high precision in inkjet printheads is a complex undertaking. DPI and PASS count constitute the outward manifestation of precision, while mechanical resolution, droplet volume, and ejection frequency form the hardware foundation. The coordination mechanism between the X and Y axes determines the final printing result.

In practical applications, it's crucial to avoid the misconception of prioritizing precision above all else and instead optimize parameter combinations based on production speed, media type, and inkjet ink characteristics. With the continuous evolution of technologies such as staggered nozzles and variable droplets, printheads are achieving breakthroughs in both precision and efficiency, enabling a wider range of industrial applications.

Copyright © 2020-2022 Fnetlink.com All Rights Reserved.豫公网安备 41019702002145号 Zhengzhou Hongsam Digital Science and Technology Co., Ltd. 豫ICP备11004347号

Consult

+86 19036977269

+86 19036977269

Top