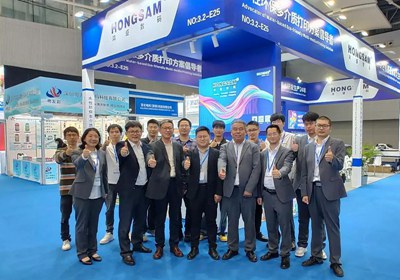

Exhibition Report | 2025 FESPA Global Print Expo - Berlin

On May 6th, the four-day 2025 FESPA Global Printing Expo in Berlin, Germany has successfully opened. As a global event in the digital printing industry, the presence of HONGSAM is certainly indispensable. At this exhibition, HONGSAM showcased its full range of inkjet inks (digital printing, photographic printing, digital textile printing) and three different digital printing solutions. JETALL® water-based latex printing remained the highlight of the exhibition, becoming a major hotspot in the event.