DTF Washing Free Disperse Ink

- ▪ Washing free.

- ▪ Good dry and wet fastness.

▪ Good permeability, especially for carpets.

Brief Information

Brief Information

Brand:DTFTM

Colors:C、M、Y、K、FM FY BLANK;

Suitable Printheads:EPSON、SEIKO、KYOCERA、RICOH 、KM、STARFIRE

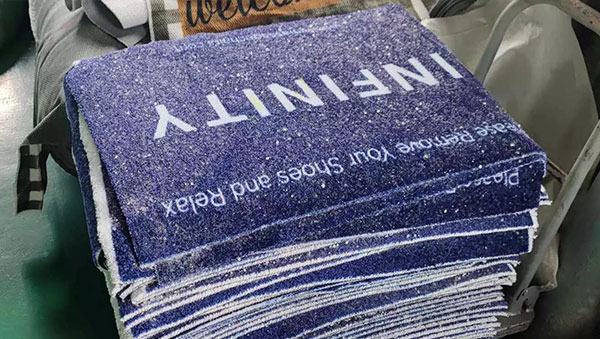

Application:Polyester carpet, modified polyester carpet, polyester towel, beath towel, etc.

Auliaries:Pre-treatment liquid for disperse ink DP-03/DP-04.

Product Advantages

Product Advantages

▪ By using Hongsam DTF washing-free dispersed ink for carpet, there is no need washing.

▪ It has good dry and wet fastness. For materials that are not resistant to high temperatures, it can achieve good dry and wet rubbing fastness under the same color development conditions, which effectively solves customer production quality problems.

▪ Good permeability, especially for digital carpet printing.

Hongsam DTFTM (direct to fabric) washing free direct printing disperse ink can ensure that the product has good dry and wet fastness even without washing process. Through experiments, we use ordinary disperse ink and Hongsam DTF washing free disperse ink to print on polyester carpets. After color development, the wet and dry rubbing fastnesses of DTF wash-free disperse ink are compared simultaneously without washing. It can be intuitively seen that the dry and wet rubbing fastness degree of DTF washing free disperse ink is 1-2 higher than that of ordinary dispersion ink.

Product Qualification

Product Qualification

Printing Show

Printing Show

Product Development Background

Product Development Background

Due to the color floating after development, many users face the problem of poor dry and wet rubbing fastness when mentioning polyester carpet digital direct printing products. If the printed product is not washed after the direct printing process, the wet and dry rubbing fastness will easily fail to meet the customer's requirements. However, if the printed product is washed and dried, a large amount of energy will be consumed. In addition, environmental protection policies have gradually become stricter in recent years. Many users either do not have the conditions for washing, or the conditions for washing are restricted. In short, it has adversely affected the final production and product quality.

How to solve the problem of washing of polyester carpet direct-injection digital printing? Can we skip the washing step and directly meet customer needs in terms of dry and wet rubbing fastness? In response to such market pain points, Hongsheng Digital developed and launched DTF washing-free dispersed dye ink in response to the country's environmental protection requirements and in line with market demand.