Sep 29,2025

Sep 29,2025

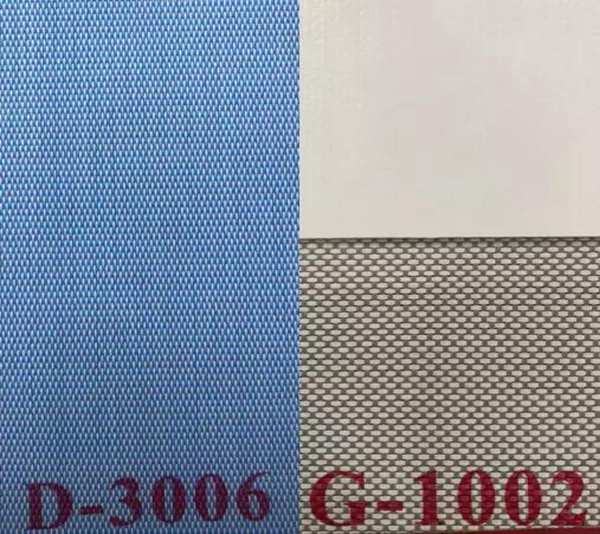

It is not difficult to see from this thick product catalog that sunshade fabric printing is another industry dominated by "involutioners", with hundreds of material samples available, including different material types, weaving methods, and texture backgrounds. Different paths lead to the same destination. Similar to the fabric and leather industries, everyone is facing problems of homogenization, excessive competition, and large inventory. The emergence of latex solutions provides some innovative ideas for products in the sunshade industry.

How to achieve breakthroughs and product upgrades in the sunshade fabric industry? Get rid of the current industry quagmire? Let me introduce it to you in detail!

Sunshade fabric is specialized of blocking UV and transmitting light. Its core characteristics are sun protection, heat insulation, and transparency, which can effectively block ultraviolet rays and reduce indoor temperature, while also meeting certain lighting needs.

Common sunshade fabrics are mainly divided into three categories:

-Polyester Fiber Fabric: High cost performance, wear-resistant and sun resistant, is currently the mainstream in the market, often used for printing or solid color design.

-Fiberglass Fabric: It has stronger high temperature resistance, fire resistance and flame retardancy, and is mostly used in public buildings or scenes with fire protection requirements.

-PVC Coated Fabric: Good waterproof performance, with a shading rate of over 90%, suitable for damp or heavily shaded areas such as balconies and sunrooms.

It is not difficult to see its basic characteristics and functional requirements from the types and uses of fabrics:

1. The fabric types are complex, with a majority of blended composite materials, and cannot be classified and produced using traditional digital printing techniques!

2. The requirement for sun fastness is extremely high, and it also has functional requirements such as waterproofing and flame retardancy.

3. Home use must meet eco-protection requirements. All of the above perfectly match the characteristics of latex printing.

Latex printing has the following technological advantages:

• Superior Environmental Performance: Latex ink adopts a pure water-based formula, does not contain organic solvents, has no VOCs emissions, meets environmental standards, and has obtained OEKO-TEX® ECO PASSPORT certification. It can be used to produce textiles that come into direct contact with the human body, ensuring safety and reliability. No problem for Home curtain applications!

• Wide Material Adaptability: It can directly print textiles without coatings or outdoor coatings, breaking the traditional dependence. Whether it is ordinary cotton and linen fabrics, or high elasticity and waterproof fabrics with special properties, it can achieve precise printing. When we can print on every materials in hand, traditional product innovation methods would be broke away. In the future, product competition will become competition of creative and design!

• Excellent Printing Effect: The water-based nano pigment system makes the printed colors brilliant, and the wide color gamut ink can achieve gradient and fluorescent color formation in one go. The pattern has good weather resistance and is not faded or aged after long-term exposure to light, temperature changes, and other environments. Perfectly matching the demand for high sun exposure products.

• High Production Efficiency: The Hong-Jet HJ-1808L latex printer can achieve a high-speed output of 60㎡ per hour, which can meet the needs of large-scale textile production. The equipment runs stably, reducing downtime and improving production efficiency.

• Short Process Flow: Latex printing does not require tedious procedures such as sizing and washing, reducing production processes, lowering production costs, and also reducing water resource waste, in line with the concept of green production. Both material manufacturers, agents, and even creative companies can achieve product differentiation.

Nowadays, various industries are talking about involution and low-price competition. We may not be a changer of this close-quarter fighting industry, but only change can drive development, and only innovation can make customers willingly pay. Hong-Jet Latex Solution, with its innovative technological characteristics, adds a fresh new driving force to the industry!